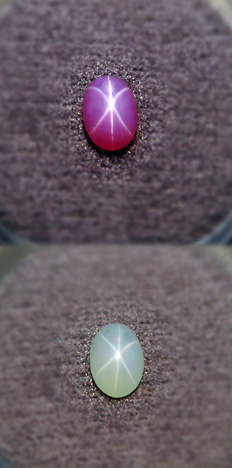

| The creation of star sapphires is just a slight modification of the standard Verneuil process for the creation of synthetic corundum. The feed mixture is doped with 0.1-0.3% titanium dioxide.

Explain Verneuil process: Process animation

After the boule is grown it is transparent as the titanium dioxide is fully dissolved in the boule at the formation temperature. After cooling the boule is reheated to 1300 C and held at temperature for 24 hours. This "re-heat" causes the dissolved titanium dioxide to precipitate as fine needles of the mineral rutile.

In the early attempts the needles tended to migrate during precipitation to the surface of the boule. This created imperfect stars after cutting. Eventually it was discovered that the growing boule needed to be cycled in temperature during the growth process creating multiple layers of solidified areas between the growing areas.

This multi-layered boule decreases the mobility of the titanium dioxide in the second step. This produces strong and well centered stars.

The process was abandoned in about 1974 when cheaper over seas production took over the market.

|