There is Good News and there is .... Bad News

The good news is that synthetic facet rough is readily available, and of very high quality. The price has stabilised for the most part, and it can be purchased for just penny's per carat. It can be ordered in sizes acceptable to most everyone.

As far as natural rough is concerned, the very best gets picked out overseas before it ever reachers our markets, so even our very best is typically not museum quality. That's not all bad as much of this material is still very useful and will cut nice stones. Once in a while high quality material does make it to our shores, but you can bet you will pay a premium for it.

Larger size clean rough always costs more than smaller size clean rough. It is becoming more difficult to tell if some rough is actually natural or synthetic. The synthetic quartz materials (rock crystal, amethyst, citrine, and ametrine) all have most of the same physical characteristics as the natural. They can sometimes be differentiated by their internal twinning. The synthetic material is usually twin free, and the natural may have twining patterns. This is less than reliable though, as it is only conclusive when twining is present and not when it is absent. (from: Gems & Minerals, Fall 1986)

Here is a simple "polarscope" made up of a jar of REFRACTOL and two pieces of polarizing material. (Available form places like Edmund Scientific.)

Here is the resultant interference pattern as viewed with the amethyst between the two pieces of polarizing material. Twinning is present.

So here is the first bit of bad news: there is facet rough out there which is actually synthetic, but purports to be the real thing. Some of the newer synthetic technologies now use inferior natural rough as a starting material. Some use processes to grow the synthetic that are similar to the natural methods, and hence they are becoming harder and harder to differentiate. Man-made (recrystalized) ruby has made its way back to Burma where it is being sold as the real thing. (So just a little warning - Buyer Beware!)

So here comes the really bad news for most beginning facetors. You need to understand the math! Being able to count in order to follow a facet diagram is handy, but being able to calculate the "real" price of faceting rough may be more important. Remember you are paying the same price for he final gem weight as the weight of the powder you create in the process. Grinding creates lots of powder!

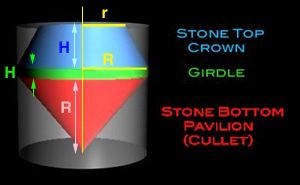

Let's examine a hypothetical piece of rough, that we were lucky enough to find nicely formed into a perfect cylinder for cutting a round stone.

Volume Math

Vol Frustum = 1/3 x

pi

x (R

2

+ Rr + r

2)

x H

(crown)

Vol Cylinder =

pi

x r

2

x H

(girdle)

Vol Cone = 1/3 x

pi

x r

2

x H

(pavilion)

Overall the CYLINDER

of rough is

29 mm high x 15 mm diameter

volume = 3.14 x (7.5)

2

x 29 =

5122

3mm

|

Cut Stone Volume = |

1118 + 353 + 1059 = 2330 3mm |

|

|

|

|

|

= 0.455 |

|

|

|

|

45.5 % of stone remains, therefore we lost 54.6% |

|

Frustum = ( Top of

Stone )

1/3 x 3.14 x [ (7.5) 2 + (7.5 x 5) + (5)

2 ] x 9

= 1118 3mm

Cylinder = ( Girdle

)

3.14 x (7.5)

2

x 2 = 353

3mm

Cone = ( Bottom of

Stone )

1/3 x 3.14 x (7.5)

2

x 18 = 1059

3mm

So, if you are off to purchase some facet rough that cost $3 a carat, it actually means that the rough to finished stone cost will be $6 a carat. When you buy facet rough you should multiply by at least 2x and likely 2.5x to get an estimate of how much it actually is costing you to make the finished stone. Typically you can count on a 50% to 65% loss on cutting. Even rectangular stones from elongated crystals have fairly high loss.